M-JET+ Hazard Monitoring System

Technical specifications

The M-JET+ Hazard Monitor is an all new, state of the art, multi-function Hazard Monitor designed for maximum reliability. The programmable microprocessor-based system monitors the proper and safe operation of bucket elevators, belt conveyors, chain conveyors or screw conveyors in ATEX or hazardous location areas. In the event of equipment malfunction or operation beyond user programmed limits, the M-JET+ Hazard Monitor provides a safe and controlled equipment shutdown.

It is the first Hazard Monitor approved for ATEX Zone and Level 2 of the SIL safety standard. The M-JET+ boasts dual-microprocessor design, built-in system and sensor diagnostics, and intuitive and user-friendly display and programming interface.

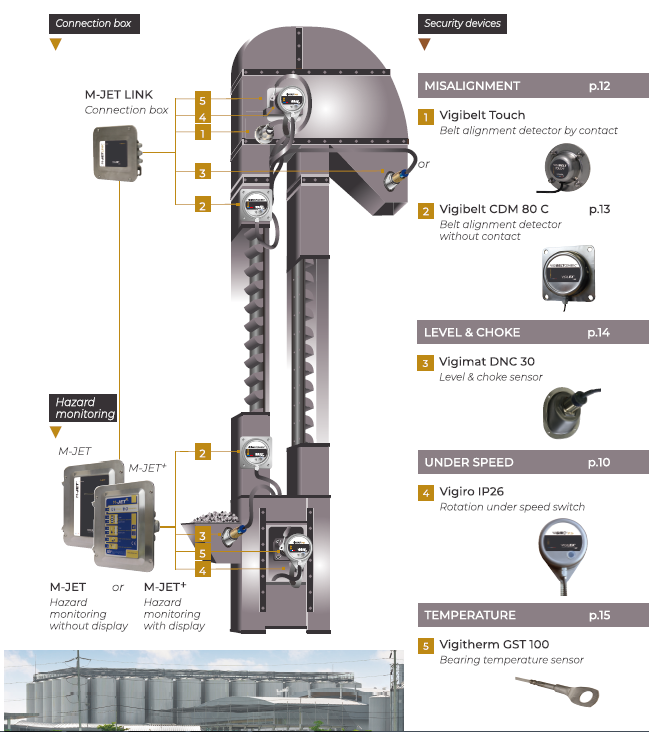

The monitoring and fault diagnosis are performed by means of ATEX and hazardous location compatible sensors connected to the M-JET+ Hazard Monitor.

EQUIPMENT FUNCTIONS MONITORED:

- Belt misalignment: VIGIBELT sensor x4

- Rotational speed of the driving pulley: VIGIRO sensor x1

- Rotational speed of the driven pulley: VIGIRO sensor x1

- Pulley bearing temperature: VIGITHERM sensor x4

- Temperature of the drive motor or gearbox: VIGITHERM sensor x1

- Level or choke on the conveyor input: VIGIMAT sensor x1

- Level or choke on the conveyor output: VIGIMAT sensor x1

M-JET+’S UNIQUE FEATURES INCLUDE:

- Intuitive and easy to use interface for setting alarm thresholds

- USB port to import/export user settings & download historical data

- Optional Ethernet port enables local network monitoring & connection to PLCs

- Optional M-JET.COM for remote monitoring of M-JET+ systems via the Cloud and Internet & text/email notification

- User selectable language: English, French, German, Spanish or Italian

Download

See all downloads

DOC SENSOR JET SYSTEM 2022

DOC SENSOR JET SYSTEM 2022